Project Title:

Accelerated nanobainitic transformation in low-alloy steels processed by incremental forging.

Project Acronym:

NanoBainControl

Financial support of the National Science Centre (Poland), M-ERA.NET 2 Call 2020, 2020/02/Y/ST8/00107 (AGH-UST project no. 28.28.110.70540)

- AGH University of Krakow || Faculty of Metals Engineering and Industrial Computer Science (WIMiIP) || Department of Metal Forming and Metallurgical Engineering

- Silesian University of Technology || Faculty of Materials Engineering || Department of Materials Technology

- TU Bergakademie Freiberg || Faculty of Materials Science and Technology || Institute of Metal Forming

- Principal Investigators – Prof. PhD Eng. Ulrich Prahl; PhD, DSc. Eng. Marek Wojtaszek; PhD, DSc. Eng. Magdalena Jabłońska

=============================================================================================================================================================

General Project Description

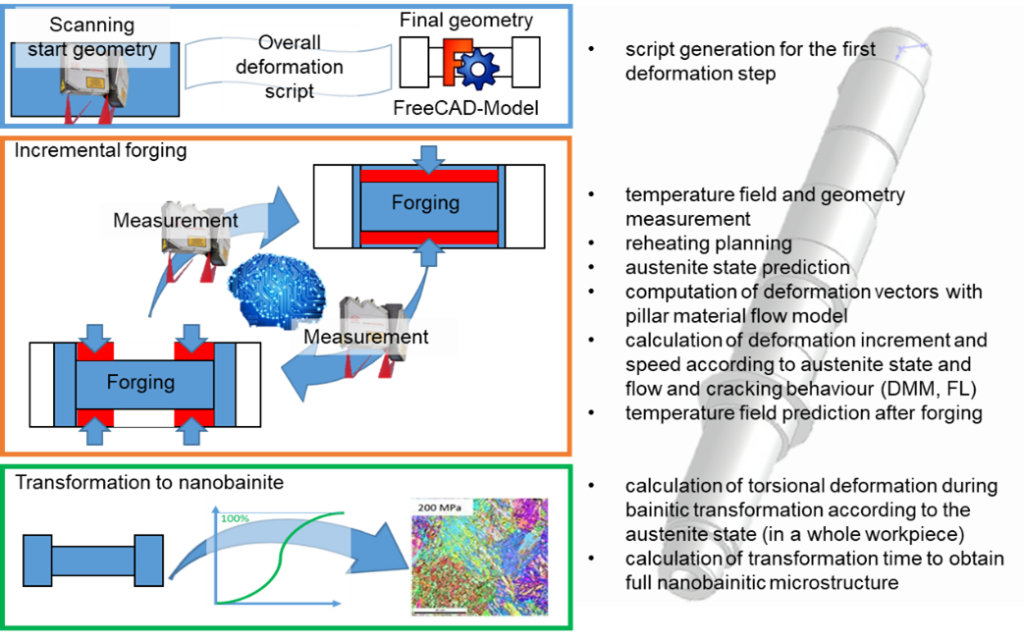

A project concept is based on the assumption that all microstructural and thermo-mechanical phenomena occurring during an incremental forging process and a subsequent heat treatment can be efficiently and precisely controlled in a real time by a dedicated online calculation system. To achieve this, the integration of many individual machines and devices in the production cell with a digital twin of the process (including relevant calculation models) is necessary. The equipment has to work in parallel with monitoring of an actual workpiece geometry and temperature profile. Based on these actual data, the system will quickly determine model deformation strategy for the subsequent forging or decide to reheat a workpiece. After forging, the system will determine parameters of cooling and the nanobainitic transformation. Due to the high-speed high-volume data transfer, that is necessary but a common programmable logic controller (PLC) cannot handle, a fast fuzzy logic controller (FLC) on additional workstation will be applied. The comprehensive material investigations and numerical simulations are needed for parametrisation of the calculation models and for defining the FLC functioning. The factors, which must be taken into consideration by the online calculation system, are listed in figure below (ordered as they appear in the process chain).

The state of the art is that the phenomenon of accelerating bainitic transformation for non-nanobainite steels can be obtained by application of external stress – this constitutes the starting technology readiness on the first level. The defined main objective of the project combines three different scale of consideration of this issue. The micro-scale approach (characterization of the material subjected to specific tests) will provide the knowledge necessary to formulate conditions of forging and nanobainitic transformation process, and thus to achieve the TRL2. The meso-scale approach is going to prove the concept, both analytically and experimentally (TRL3) while the macro-scale approach will bring the TRL4 – a technology validated in laboratory conditions. The application of tension or compression stresses during bainite transformation of large forged parts can be problematic. However, torsional shear stress can be simply applied. With regard to the technology under consideration, pure shear state of stress was not considered due to the lack of sufficient available knowledge about the issue. This stress state gives the opportunity to separate the volumetric change and transformation induced plasticity and a chance of essential understanding of Gibbs energy balance due to the mechanical stabilization of austenite (high dislocation density), stress induced transformation and chemical driving force. Forgeability of high carbon steels like nanobainite steels is limited due to their susceptibility to cracking, therefore properly determined and applied hermomechanical processing parameters are essential for successful design of forging cycles. For controlling and predicting the flow behaviour of the material during hot deformation carried out at various combinations of temperatures and strain rates, processing maps based on DMM theory can be developed. Applying processing maps to predict microstructural behaviour of hot formed material and defining the combination of processing parameters, such strain, temperature, and strain rate, which are the most beneficial for processing of the analysed material. The flow behaviour and microstructural changes of various alloys, as well as the development of these materials processing windows based on DMM theory have been presented in many recent publications.

Project Team AGH

- PhD, DSc. Eng. Marek Wojtaszek, Prof. AGH

- PhD, DSc. Eng. Aneta Łukaszek-Sołek, Prof. AGH

- PhD, DSc. Eng. Tomasz Śleboda, Prof. AGH

- PhD, Eng. Krystian Zyguła

- PhD, Eng. Łukasz Lisiecki

- PhD, DSc. Eng. Barbara Mrzygłód, Prof. AGH

- M.Sc., Eng. Kamil Cichocki

- M.Sc., Eng. Wiktoria Skonieczna

- M.Sc., Eng. Kamil Gryboś

Project Team Silesian University of Technology

- PhD, DSc. Eng. Magdalena B. Jabłońska – Project manager

- PhD, DSc. Eng. Kinga Rodak, Prof. PŚ

- PdD, Eng. Marek Tkocz

- PdD, Eng. Iwona Bednarczyk

- PdD, Eng. Karolina Kowalczyk

- M.Sc., Eng. Mikołaj Konofol

- M.Sc., Eng. Michał Kostka

- M.Sc., Eng. Mateusz Wesołowski

Publications

- Marek Wojtaszek, Krystian Zyguła. Fast estimation of favorable parameters of hot metal forming using the fuzzy logic method (Szybkie szacowanie korzystnych parametrów przeróbki plastycznej na gorąco z wykorzystaniem metody logiki rozmytej) Forming 2022 : streszczenia referatów i posterów 29. międzynarodowej konferencji Forming : 7–10.9.2022, Polanica Zdrój (The book of abstracts of the 29th international conference Forming). Stowarzyszenie Absolwentów Wydziału Metalurgii i Inżynierii Materiałowej Politechniki Śląskiej, Gliwice: Sieć Badawcza Łukasiewicz – Instytut Metalurgii Żelaza, [2022]. — ISBN: 978-83-958775-5-1, s. 54

- M. Wojtaszek, Ł. Lisiecki, A. Łukaszek-Sołek, G. Korpała, K. Zyguła, T. Śleboda, M.B. Jabłońska, U. Prahl, Application of processing maps and numerical modelling for identification of parameters and limitations of hot forging process of 80MnSi8-6 steel, Arch. Civ. Mech. Eng. 23 (2023). https://doi.org/10.1007/s43452-023-00783-8.

- Iwona Bednarczyk, Magdalena B. Jabłońska, Marek Tkocz, Karolina Kowalczyk, Grzegorz Korpała, Marek Wojtaszek: Wpływ prędkości odkształcenia na zmiany mikrostruktury i właściwości stali 80MnSi8-6, po odkształceniu plastycznym na gorąco przy użyciu symulatora WUMSI – Influence of the strain rate on changes in the microstructure and properties of 80MnSi8-6 steel after hot plastic deformation using the WUMSI symulator. Materiały konferencyjne: OMIS’2022: Odkształcalność Metali i Stopów. XIV konferencja naukowa: 22–25 listopada 2022, Łańcut: materiały konferencyjne, rozszerzone streszczenia, abstracts. Sekcja Procesów Technologicznych Komitetu Inżynierii Materiałowej i Metalurgii PAN, Katedra Przeróbki Plastycznej Politechniki Rzeszowskiej, Rzeszów. Oficyna Wydawnicza Politechniki Rzeszowskiej 2022. ISBN: 978-83-7934-614-1. s. 26–27. Tekst pol.-ang.

- Marek Tkocz, Magdalena B. Jabłońska, Iwona Bednarczyk, Karolina Kowalczyk, Mikołaj Konofol, Grzegorz Korpała, Ulrich Prahl, Marek Wojtaszek. The shear stress-assisted bainitic transformation in the low-alloy nanobainitic steel. Conference materials: AMT’2023: Advanced Materials and Technologies, June 18th – 21st 2023, Wisła, Poland. Book of abstracts: eds. Adam Skowronek, Aleksandra Kozłowska. Katowice – Gliwice: Archives of Foundry Engineering, cop. 2023, ISBN: 978-83-63605-57-5, s. 106.

- Marek Tkocz, Magdalena B. Jabłońska, Iwona Bednarczyk, Mikołaj Konofol, Grzegorz Korpała, Marek WOJTASZEK, Ulrich Prahl: Przemiana nanobainityczna w stali 80MnSi8-6 w warunkach ścinania – Nanobainitic transformation in 80MnSi8-6 steel under shear loading. Materiały konferencyjne: Materiały konferencyjne: PLASTMET’2023: zintegrowane studia podstaw deformacji plastycznej metali. XIII konferencja naukowa: 7–10 listopada 2023, Łańcut: streszczenia – Integrated studies of foundations of plastic deformation of metals. Book of abstracts / Sekcja Procesów Technologicznych Komitetu Inżynierii Materiałowej i Metalurgii PAN, Sekcja Mechaniki Materiałów Komitetu Mechaniki PAN. Rzeszów: Oficyna Wydawnicza Politechniki Rzeszowskiej, 2023. ISBN: 978-83-7934-688-2, s. 144–145.

- Krystian Zyguła, Kamil CichockiI, Karolina Kowalczyk, Grzegorz Korpała, Marek Wojtaszek, Magdalena Jabłońska, Ulrich Prahl. Microstructure prediction of 80MnSi8-6 steel after hot deformation based on JMAK model and FEM simulation. Conference materials: AMT’2023: Advanced Materials and Technologies, June 18th – 21st 2023, Wisła, Poland. Book of abstracts: eds. Adam Skowronek, Aleksandra Kozłowska. Katowice – Gliwice: Archives of Foundry Engineering, cop. 2023, ISBN: 978-83-63605-57-5, s. 196.

- Marek Wojtaszek, Krystian Zyguła Grzegorz Korpała, Ulrich Prahl. Logika rozmyta jako metoda szybkiej analizy parametrów i ograniczeń obróbki na gorąco stali 80MnSi8-6 na podstawie testów plastometrycznych – Fuzzy logic as a method of fast analysis of parameters and limitations of hot forming of 80MnSi8-6 steel based on plastometric tests. Materiały konferencyjne: XIII konferencja naukowa PLASTMET’ 2023: zintegrowane studia podstaw deformacji plastycznej metali, 7–10 listopada 2023, Łańcut: Integrated studies of foundations of plastic deformation of metals: book of abstracts. Sekcja Procesów Technologicznych Komitetu Inżynierii Materiałowej i Metalurgii PAN, Sekcja Mechaniki Materiałów Komitetu Mechaniki PAN. Rzeszów: Oficyna Wydawnicza Politechniki Rzeszowskiej, 2023. — ISBN: 978-83-7934-688-2, s. 56–57.

- Marek Wojtaszek, Łukasz Lisiecki, Grzegorz Korpała, Michał Puławski, Aneta Łukaszek-Sołek, Krystian Zyguła, Magdalena Jabłońska, Ulrich Prahl. Identification of parameters and limitations of selected multi-step hot forging process of 80MnSi8-6 steel. Conference materials: AMT’2023: Advanced Materials and Technologies, June 18th – 21st 2023, Wisła, Poland. Book of abstracts: eds. Adam Skowronek, Aleksandra Kozłowska. Katowice – Gliwice: Archives of Foundry Engineering, cop. 2023, ISBN: 978-83-63605-57-5, s. 113.

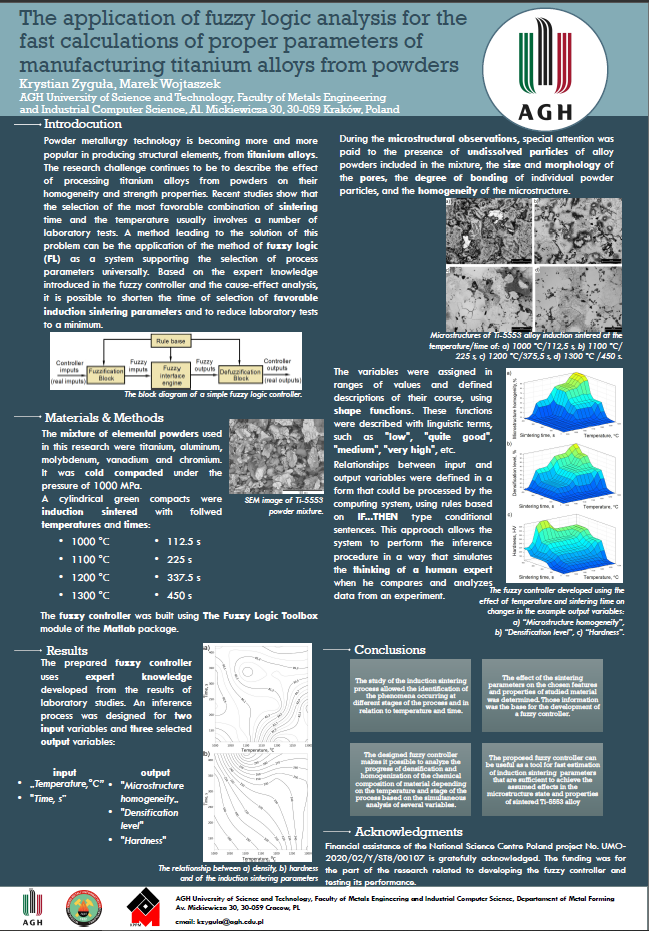

- Krystian Zyguła, Marek Wojtaszek. The application of fuzzy logic analysis for the fast calculation of proper parameters of manufacturing titanium alloys obtained from powders (Zastosowanie metody logiki rozmytej do szybkiego szacowania parametrów wytwarzania stopów tytanu otrzymanych z proszków). Forming 2022: streszczenia referatów i posterów 29. międzynarodowej konferencji Forming: 7–10.9.2022, Polanica Zdrój (The book of abstracts of the 29th international conference Forming). Stowarzyszenie Absolwentów Wydziału Metalurgii i Inżynierii Materiałowej Politechniki Śląskiej, Gliwice: Sieć Badawcza Łukasiewicz – Instytut Metalurgii Żelaza, [2022]. — ISBN: 978-83-958775-5-1, s. 56.

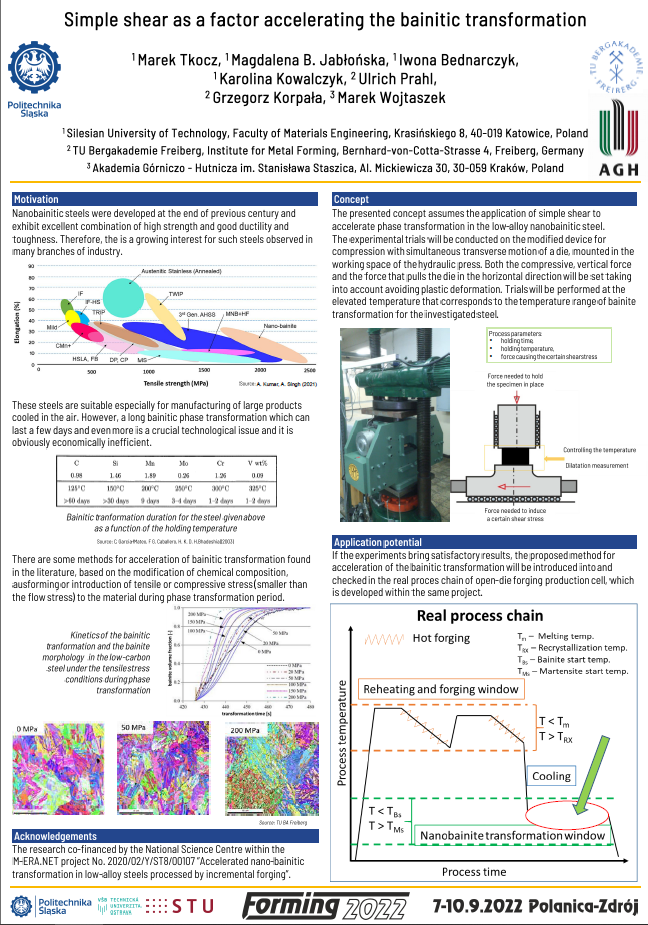

- Marek Tkocz, Magdalena Jabłońska, Iwona Bednarczyk, Karolina Kowalczyk, Ulrich Prahl, Grzegorz Korpała, Marek Wojtaszek. Simple shear as a factor accelerating the bainitic transformation. Forming 2022: streszczenia referatów i posterów 29. międzynarodowej konferencji Forming: 7–10.9.2022, Polanica Zdrój. (The book of abstracts of the 29th international conference Forming). Stowarzyszenie Absolwentów Wydziału Metalurgii i Inżynierii Materiałowej Politechniki Śląskiej. — Gliwice: Sieć Badawcza Łukasiewicz – Instytut Metalurgii Żelaza, [2022]. — ISBN: 978-83-958775-5-1, s 48.

- Marek Tkocz, Grzegorz Korpała, Magdalena Jabłońska, Marek Wojtaszek, Urlich Prahl. Koncepcja wykorzystania stanu czystego ścinania do przyspieszenia przemiany fazowej w stali nanobainitycznej. (A concept for the application of shear stress state to accelerate phase transformation in the nanobainitic steel). PLASTMET’2023: zintegrowane studia podstaw deformacji plastycznej metali: XIII konferencja naukowa: 7–10 listopada 2023, Łańcut: Integrated studies of foundations of plastic deformation of metals. Book of abstracts. Sekcja Procesów Technologicznych Komitetu Inżynierii Materiałowej i Metalurgii PAN, Sekcja Mechaniki Materiałów Komitetu Mechaniki PAN. Rzeszów: Oficyna Wydawnicza Politechniki Rzeszowskiej, 2023. ISBN: 978-83-7934-688-2, s. 63-64.

Open access to publication:

Application of processing maps and numerical modelling for identification of parameters and limitations of hot forging process of 80MnSi8‑6 steel

Conferences

The results of the conducted research were presented at several conferences in the form of oral presentation and posters:

- Marek Wojtaszek: The application of fuzzy logic analysis to fast calculation of proper parameters of manufacturing the P/M composites based on Ti alloys reinforced in-situ. 29th International Conference Forming. Polanica Zdrój, Poland, 7-10.09.2022.

- Marek Wojtaszek: Identification of parameters and limitations of selected multi-step hot forging process of 80MnSi8-6 steel. Form of participation in the conference: oral presentation. AMT’2023 conference: Advanced Materials and Technologies: June 18th – 21st 2023, Wisła, Poland. Współautorzy prezentacji: Co-authors: Marek Wojtaszek,, Łukasz Lisiecki, Grzegorz Korpała, Michał Puławski, Aneta Łukaszek-Sołek, Krystian Zyguła, Magdalena Jabłońska, Ulrich Prahl.

- Marek Wojtaszek: Logika rozmyta jako metoda szybkiej analizy parametrów i ograniczeń obróbki na gorąco stali 80MnSi8-6 na podstawie testów plastometrycznych. XIII Conference: Integrated studies of foundations of plastic deformation of metals PLASTMET 2023. Łańcut, Poland, 7.11.2023 – 10.11.2023.

- Marek Tkocz , M. B. Jabłońska, I. Bednarczyk, K. Kowalczyk,M.Konofol, G. Korpała, U. Prahl, M. Wojtaszek: The shear stress-assisted bainitictransformation in the low-alloy nanobainitic steel. Conference: Advanced Materials and Technologies AMT’2023 18.06.2023 – 21.06.2023.

- Krystian, Zyguła: The application of fuzzy logic analysis for the fast calculations of proper parameters of manufacturing titanium alloys from powders.

- M. Tkocz: Simple shear as a factor accelerating the bainitic transformation International Conference: Forming 2022, 7–10.9.2022, Polanica Zdrój. Co-authors: Magdalena Jabłońska, Iwona Bednarczyk, Karolina Kowalczyk, Ulrich Prahl, Grzegorz Korpała, Marek WOJTASZEK

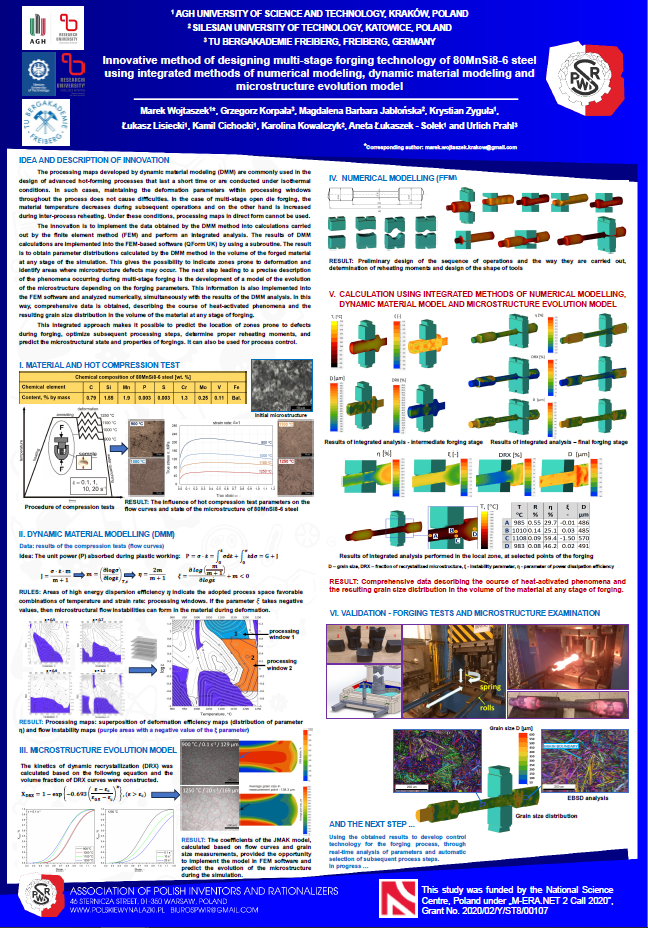

- Marek Wojtaszek: Innovative method of designing multi stage forging technology of 80MnSi8-6 steel using integrated methods of numerical modeling, dynamic material modeling and microstructure evolution model.

- Krystian Zyguła: Microstructure prediction of 80MnSi8-6 steel after hot deformation based on JMAK model and FEM simulation. Form of participation in the conference – poster. AMT’2023 conference: Advanced Materials and Technologies: June 18th – 21st 2023, Wisła, Poland. Co-authors: Kamil Cichocki, Karolina Kowalczyk, Grzegorz Korpała, Marek Wojtaszek, Magdalena Jabłońska, Ulrich Prahl.

Awards

- Silver medal: The international trade fair “Ideas – Inventions – New Products” iENA 2023. Nuremberg, Germany, 28.10.2023 – 30.10.2023. Innovative method of designing multi-stage forging technology of 80MnSi8-6 steel using integrated methods of numerical modeling, dynamic material modeling and microstructure evolution model.

- Bronze medal: Seul International Invention Fair (SIIF), Seul, Korea, 1.11.2023 – 11.2023. Innovative method of designing multi-stage forging technology of 80MnSi8-6 steel using integrated methods of numerical modeling, dynamic material modeling and microstructure evolution model

Diploma Projects

- Engineer’s Thesis:

„Analysis of microstructure and properties of 80MnSi8-6 steel” – Eng. Mateusz Wesołowski,

The engineering thesis defenced at 28.01.2022,

Supervisor: PhD, Eng. Iwona Bednarczyk

„The influence of finite element method (FEM) simulation parameters on the accuracy of hot compression representation. Wpływ parametrów symulacji metodą elementów skończonych (MES) na dokładność odwzorowania procesu spęczania na gorąco.” – Eng. Stanisław Marek,

Engineer’s Thesis defended at AGH University of Krakow in 2023.

Supervisor: PhD Eng. Krystian Zyguła,

- Master’s Thesis:

„Determination of microstructure evolution in 80MnSi8-6 steel deformed in WUMSI simulator” -M.Sc., Eng. Mateusz Wesołowski,

The master’s thesis defenced at 28.09.2023,

Supervisor: PhD Eng. Iwona Bednarczyk

„The influence of the shear process on the possibility of accelerating the bainitic transformation in steel” -M.Sc., Eng. Mikołaj Konofol,

The master’s thesis defenced at 28.09.2023,

Supervisor: PhD Eng. Marek Tkocz

„Development of parameters for an automated, multi-operational open die forging process of low-alloy steel with a nanobainite structure.– Opracowanie parametrów zautomatyzowanego, wielooperacyjnego procesu kucia swobodnego stali niskostopowej o strukturze nanobainitycznej.” – M.Sc. Eng. Iga Moskalik

Master’s thesis defended at AGH University of Krakow, at 28.10.2022.

Supervisor: PhD Eng. Łukasz Lisiecki,

„Selection of open die and semi-open die cogging process parameters of elements made of low-alloy steel, taking into account the minimization of defects in the final product.– Dobór parametrów wydłużania swobodnego i półswobodnego elementów ze stali niskostopowej z uwzględnieniem minimalizacji wad wyrobu gotowego.” – M.Sc. Eng. Kamil Gryboś

Master’s thesis defended at AGH University of Krakow at 24.10.2023.

Supervisor: PhD Eng. Łukasz Lisiecki